| Flaw Detector | Fruit Hardness tester | Rockwell hardness tester | Force gauge | Thickness gauge |

[News] Sterilizer and Distiller

[News] Force Gauge

[Notice] Rockwell Hardness tester

[Event] New Hardness tester on li

[News] We have become the member

[News] UFD610 Ultrasonic Flaw de

[Promote] Fruit Hardness Tester

[News] Force Gauge

[Notice] Rockwell Hardness tester

[Event] New Hardness tester on li

[News] We have become the member

[News] UFD610 Ultrasonic Flaw de

[Promote] Fruit Hardness Tester

[News] Sterilizer and Distiller

[News] Force Gauge

[Notice] Rockwell Hardness tester

[Event] New Hardness tester on li

[News] We have become the member

[News] UFD610 Ultrasonic Flaw de

[Promote] Fruit Hardness Tester

[News] Force Gauge

[Notice] Rockwell Hardness tester

[Event] New Hardness tester on li

[News] We have become the member

[News] UFD610 Ultrasonic Flaw de

[Promote] Fruit Hardness Tester

✤ Home > Products > Automatic Rockwell Hardness > Higher Model Rockwell Hardness Tester KHT800-M/KHT800-A Details

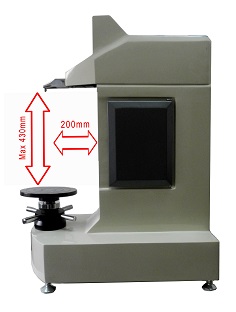

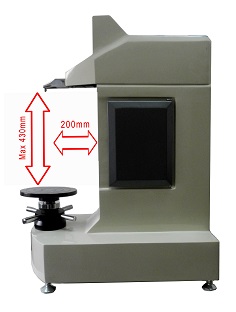

Higher Model Rockwell Hardness Tester KHT800-M/KHT800-A

[Specifications]:

· Added High Rockwell basic models;

· Testing space:430mm Max height;

· 200mm depth of throat;

[ Higher Model Rockwell Hardness Tester KHT800-M/KHT800-A Product details]:

Verticaltest height of 430mm and throat depth of 220mm.:220mm;

For KHT800-M and KHT-800-A model;

KHT800-M is a new designed, advanced Automatic Rockwell Hardness Tester, which combine similar function with stable design, It is made with Manual handle wheel pre-load,automatic main-load and testing cycle. The tester’s shape islintegrated casting body with more wide basement leads to permanent stability. Manual pre-load will be more fit users’ operational request.

New features:

Basic functions:

Standard configuration:

Verticaltest height of 430mm and throat depth of 220mm.:220mm;

For KHT800-M and KHT-800-A model;

KHT800-M is a new designed, advanced Automatic Rockwell Hardness Tester, which combine similar function with stable design, It is made with Manual handle wheel pre-load,automatic main-load and testing cycle. The tester’s shape islintegrated casting body with more wide basement leads to permanent stability. Manual pre-load will be more fit users’ operational request.

New features:

- The test force are applied via a closed-loop control unit with a load cell, a DC motor and an electronic measurement and control unit instead of traditional dead weights. The result is highly accurate measurements at all test loads up to 0.5%;

- Simple plug - and - play tech allows for much more quick and easy installation than traditional weights type machine;

- Manual handle wheel pre-load. Automatic main-load and testing cycle;

- Extended dolphin nose allows verticaltest height of 430mm and throat depth of 220mm;

- Integrated casting body with more wide basement leads to permanent stability;

- RS232 and USB port to PC;

Basic functions:

- Regular Rockwell hardness tester for metal and plastic material;

- Horizontal protrudent Indenter Design, suitable also for internal and external testing;

- Testing on Surfaces difficult to reach. Testing internal surface of rings and tubes;

- Provided with many features such as high measuring precision, wide measuring range with 15 Rockwell scales;

- The tester is suitable for testing of carbon steel, alloy steel, cast iron, non ferrous metal;

- Automatic testing cycle: Lifting of part, pre-loading, loading, dwell, unloading, results will be finished automatically;

- Measuring results digitally displaying and can be printed, or transmitted to external computer automatically by USB port;

- Test HR value can be convert to the value of HB, HV, HK and σb value;

- The tester meets all the following standard such as ISO 6508-2, ASTM E18;

- Preload:98.1N (10kgf)

- Total test force:588.4N (60kgf), 980.7N (100kgf), 1471N (150kgf)

- Scales:HRA,HRB,HRC,HRD,HRE,HRF, HRG,HRH,HRK,

- HRL,HRM,HRP, HRR,HRS,HRV

- Load dwell duration: 2~50s, can be set and stored

- Resolution :0.1HR

- Display:High definition backlight LCD

- Operation:Menu selectable, Membrane keypad

- Upper/lower limits setting & alarming

- Data statistics: Avg., Max., Min., S, R available

- Curved surface correcting automatically

- Memory: Max 400 items of test results stored automatically

- Testing Capacity:300mm (vertical), 220mm (horizontal)

- Dimensions: 690mm×280mm×860mm

- Power supply:AC, 220V/110V, 50~60Hz, 4A

- Net weight:85kg

- Gross weight:120kg

Standard configuration:

| Host machine | 1 |

| Standard hardness block for A scale | 1 |

| Standard hardness block for B scale | 1 |

| Standard hardness block for C scale | 3 |

| ball indenter (1/16″) | 1 |

| 120°cone diamond indenter | 1 |

| Mounting screws for indenter | 2 |

| Flat anvil | 1 |

| “V ”shape anvil | 1 |

| Power supply wire | 1 |

| Screwdriver for indenter mounting | 1 |

| Dust cover | 1 |

| Force Gauge | Rockwell Hardness Tester | Roughness Tester | Thickness Gauge | Flaw Detector | Webster Barcol | Hardness Tester | Vibration Tester |

Beijing Lanetech Instruments Co., Ltd. Copyright 2008-2019 All Rights Reserved

Adress:1602 Lingdi,Beiyuan Lu, Chaoyang District,100012 Beijing

E-mail:sales@lanetechworld.com angelajade@126.com

Tel:+86-10-84956391

Hot-Line:+86-10-84956391

Adress:1602 Lingdi,Beiyuan Lu, Chaoyang District,100012 Beijing

E-mail:sales@lanetechworld.com angelajade@126.com

Tel:+86-10-84956391

Hot-Line:+86-10-84956391